← Home • Products • Sample Cooler ↓ Summary • Design Example • Applications • Technical Data • Downloads

A sample cooler serves for safe sampling, cooling and if applicable condensation of hot fluids. The following descriptions are limited to water to water heat exchangers used in steam boiler plants and hot water boiler plants for the above purposes.

A sample cooler consists of a pressure vessel containing a pipe coil. The sample medium, for example boiler feed water, flows through the inside of the pipe coil, while the cooling medium, usually water, flows around the outside of the pipe coil. This results in heat being transferred from the sample medium to the cooling medium.

Installed into a complete →steam and water analysis system, sample coolers are used for both continuous sampling with fully automated on-line analysis, and for manual grab sampling with manual analysis. Available accessories include isolating valves, throttling valves, pressure relief valves, solenoid valves for high temperature shut-off, local and remote temperature indicators, local and remote flow indicators, cation exchangers, and any instrumentation for on-line water analysis.

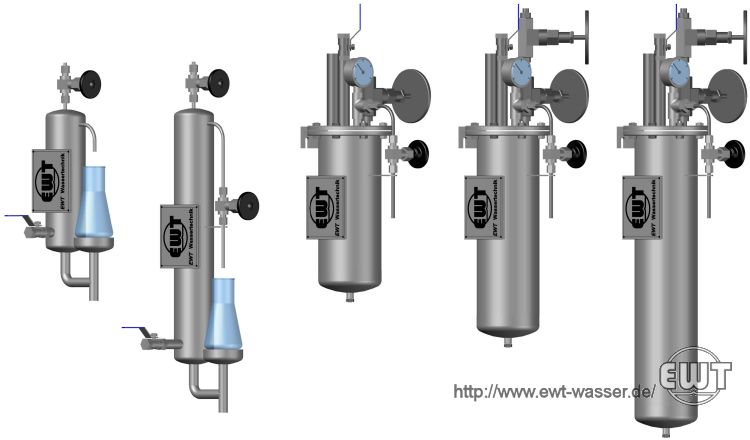

Sample coolers for manual grab sampling, different types. From left to right: Type 080-250 C and 0850-500 C, both compact design with integrated discharge funnel. Type 125-300 H, 125-400 H, and 125-600 H, each high-performance design with removable pipe coil.

| type | 080-250 C | 080-500 C | 125-300 H | 125-400 H | 125-600 H | |

| design | compact cooler | high performance cooler | ||||

| heat transfer surface area | 0.07 m² | 0.14 m² | 0.21 m² | 0.29 m² | 0.43 m² | |

| heat transfer rate, approx. | ≤ 3 kW | ≤ 10 kW | ≤ 35 kW | ≤ 60 kW | ≤ 90 kW | |

| sample mass flow | liquid | ≤ 30 kg/h | ≤ 45 kg/h | ≤ 75 kg/h | ≤ 120 kg/h | ≤ 150 kg/h |

| steam | – | – | ≤ 30 kg/h | ≤ 60 kg/h | ≤ 90 kg/h | |

| allowable pressure, max. | pipe coil | 40 bar | 160 bar (on request: 300 bar) | |||

| shell | 10 bar | |||||

| allowable temperature, max. | pipe coil | 200 °C | 250 °C | 550 °C | ||

| shell | 110 °C | |||||

| volume | pipe coil | 0.1 L | 0.2 L | 0.3 L | 0.4 L | 0.5 L |

| shell | 1.5 L | 3 L | 5 L | 6 L | 9 L | |

| Pressure Equipment Directive (PED) | Directive 2014/68/EU, article 4, section 3. Sound engineering practice. The pressure equipment must not bear the CE-marking. | |||||

| connections | inlet sample medium | tube fitting do=8 mm | butt weld end do=14 mm | |||

| outlet sample medium | pipe do=8 mm | |||||

| inlet cooling medium | threaded, female Rp 1/2" | threaded, female Rp 3/4" | ||||

| outlet cooling medium | threaded, female Rp 3/4" | |||||

| drain | – | threaded, female Rp 1/4" | ||||

| material | pipe coil | stainless steel 1.4571 | stainless steel 1.4404 (on request: 1.4539) | |||

| shell | stainless steel 1.4541 | |||||

| flange, cover | – | stainless steel 1.4571 | ||||

| gasket | – | NBR composite | ||||

| stop valve sample medium | stainless steel 1.4571 | |||||

| throttling valve sample medium | stainless steel 1.4571 | |||||

| stop valve cooling medium | stainless steel 1.4408 | |||||

| empty mass, approx. | 4 kg | 7 kg | 14 kg | 17 kg | 22 kg | |

| allowable cooling water quality | turbidity | < 5 NTU | ||||

| total suspended solids (TSS) | < 5 mg/L | |||||

| pH (¹) | 4.5 ≤ pH < 10 | |||||

| water hardness (¹) | < 2.5 mmol/L ≈ 250 ppm as CaCO3 | |||||

| chloride (¹) | < 10 ... 200 mg/L | |||||

| iron | < 0.2 mg/L | |||||

| manganese | < 0.05 mg/L | |||||

| free chlorine | < 0.5 mg/L | |||||

2025-09-29 • water treatment made in Germany • Company Information • Privacy