← Home • Products • Multi-media Filter ↓ Summary • Design Example • Applications • Technical Data • Downloads

Within the scope of water treatment, filtration ist a mainly physical process for removal of suspended solids from liquids. The liquid to be filtrated flows through a filter medium, which results in the suspended solids being retained by this filter medium. A multi-media filter ist a vessel for filtration, with a layered filter bed consisting of different filter material, for example silica sand and anthracite coal, serving as filter medium.

With increasing service life, the differential pressure between the filter inlet and out increases for a given volume flow, as more solids are being retained within the filter medium. Eventually, the filter medium needs to be either backwashed or replaced.

A multi-media filter requires periodic backwash, either with water only, or with both air and water.

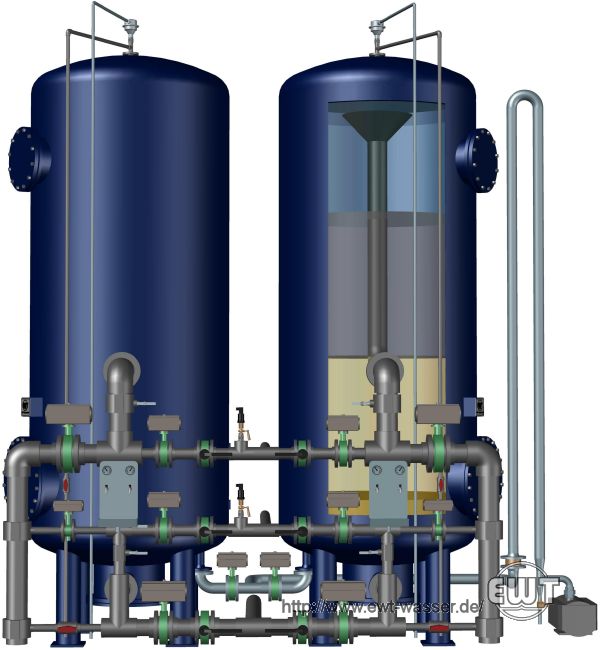

Multi-media filter plant, two lines, fully automated backwash with air and water.

| filtrate volume flow | available from approx. 1.5 up to 120 m³/h for each line | |||

| amount of lines |

usually 2x50% smaller plants also 1x100% or 2x100% larger plants also 3x33% or 4x25% |

|||

| filtration grade |

approx. 5 ... 25 μm, without flocculation approx. 0.5 ... 5 μm, with flocculation |

|||

| filtrate quality | turbidity | ≤ 0.1 ... 1 NTU | ||

| total suspended solids (TSS) | ≤ 0.5 ... 1 mg/L | |||

| differential pressure at nominal flow rate | usually ≤ 0.5 bar | |||

| operating temperature | usuually 5 ... 40 °C | |||

| backwash intervals | usually 12 ... 72 h | |||

| backwash duration |

approx. 15 minutes, for water backwash approx. 10 minutes, for air and water backwash |

|||

| backwash water volume flow | usually operating volume flow × 2 ... 4 | |||

| waste water | approx. 2 ... 80 L for each 1 m³ filtrate | |||

| recommended raw water quality | total suspended solids (TSS) | ≤ 40 mg/L | ||

| filter medium |

• anthracite coal • dolomite • garnet sand • granular activated carbon • pumice • silica sand • ... |

|||

| total service life of the filter medium |

usually ≥ 10 years for removal of suspended solids only in some cases ≤ 6 ... 12 months for special applications |

|||

| material options | pressure vessel |

• glass-reinforced plastic (GRP) • carbon steel (e.g. S235JR, P265GH) • stainless steel (e.g. 1.4301, 1.4404) |

||

| pipelines |

• polyvinyl chloride (PVC) • polypropylene (PP) • stainless steel (e.g. 1.4541) |

|||

| valves |

• polyvinyl chloride (PVC) • polypropylene (PP) • stainless steel (e.g. 1.4408) |

|||

| gaskets |

• etyhlene propylene diene monomer rubber (EPDM) • polytetrafluorethylene (PTFE) • NBR composite |

|||

| control options | differential pressure monitoring |

• local display • remote measurement |

||

| filtrate quality monitoring |

• manual sampling and analysis • continuous turbidity measurement |

|||

| line change-over |

• manually • fully automated |

|||

| backwash |

• manually • fully automated |

|||

2018-05-05 • water treatment made in Germany • Company Information • Privacy