← Home • Products • Mixed Bed ↓ Summary • Design Example • Applications • Technical Data • Downloads

Mixed bed ion exchange is an ion exchange process for polishing of →demineralised water, meaning for removal of trace dissolved solids from water.

A mixed bed ion exchanger (also: mixed bed polisher, mixed bed filter) is a vessel filled with a mixture of cation exchange resin and anion exchange resin. During service, water flows through this resin mixture. Cations dissolved in the water are then exchanged for hydrogen ions (H+), while anions dissolved in the water are exchanged for hydroxide ions (OH-). Hydrogen ions and hydroxide ions react to water.

With increasing service life, the ion exchange resins deplete. Depleted mixed bed resins are regenerated, usually with both hydrochloric acid (HCl) and sodium hydroxide (NaOH). With each regeneration, potentially acidic or alkaline waste water is produced, which may need to be neutralised. In case of smaller mixed bed exchangers, the ion exchange resin is sometimes also discarded and exchanged once depleted, rather than regenerated.

Usually, a mixed bed ion exchanger is used either as a last polishing step downstream of another demineralisation process, or as a working mixed bed for demineralisation of already partly demineralised or low-TDS water (e.g. condensate).

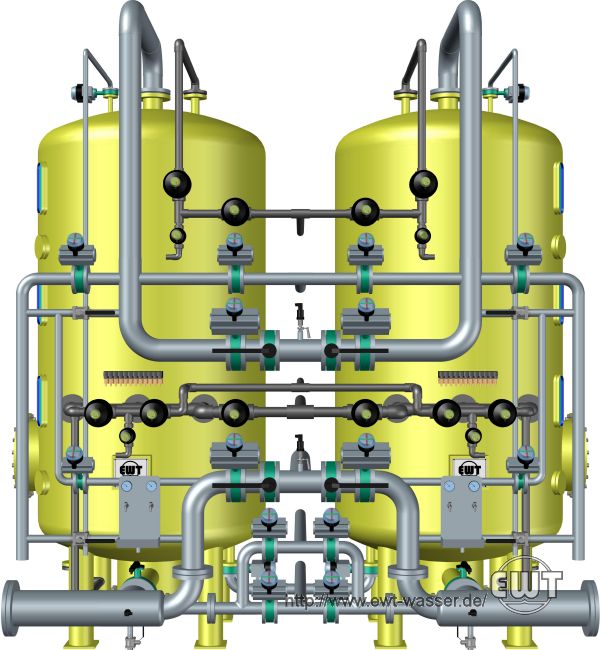

Mixed bed ion exchange plant for condensate polishing, two lines, with fully automated regeneration.

| volume flow polished water |

available from approx. 0.5 up to 350 m³/h for each line condensate polishing from approx. 1.5 up to 550 m³/h for each line |

||

| amount of lines | usually 2x100% or 1x100% | ||

| polished water quality | electrical conductivity |

≤ 0.08 μS/cm (standard) < 0.2 μS/cm (in case of unfavourable raw water quality) |

|

| sodium |

≤ 5 μg/L Na (standard) < 10 μg/L Na (in case of unfavourable raw water quality) |

||

| silicic acid |

≤ 10 μg/L SiO2 (standard) < 20 μg/L SiO2 (in case of unfavourable design conditions) |

||

| differential pressure at nominal flow | usually approx. 1 ... 1.5 bar | ||

| operating temperature |

usually 5 ... 40 °C condensate polishing ≤ 60 °C |

||

| regeneration agent | usually hydrochloric acid (HCl) and sodium hydroxide (NaOH) | ||

| regeneration intervals |

recommended ≤ 4 weeks (polishing mixed bed) usually 24 ... 240 h (working mixed bed) |

||

| regeneration duration | approx. 90 ... 120 minutes | ||

| chemical consumption |

approx. 3 ... 8 g HCl and 3 ... 9 g NaOH for each 1 m³ polished water (polishing mixed bed) approx. 10 ... 100 g HCl and 25 ... 250 g NaOH for each 1 m³ polished water (working mixed bed) |

||

| regeneration effluent discharge |

approx. 0.2 ... 0.7 L for each 1 m³ polished water (polishing mixed bed) approx. 5 ... 35 L for each 1 m³ polished water (working mixed bed) |

||

| recommended raw water quality | suspended solids (TSS) |

< 0.5 ... 1 mg/L (polishing mixed bed) < 1 ... 5 mg/L (working mixed bed with short regeneration intervals) |

|

| electrical conductivity |

≤ 0.2 ... 5 μS/cm (polishing mixed bed) ≤ 30 ... 100 μS/cm (working mixed bed) |

||

| free chlorine | < 0.1 mg/L Cl2 | ||

| total organic carbon (TOC) | ≤ 0.1 ... 0.2 mg/L C | ||

| oil, grease | < 0.1 mg/L | ||

| total service life of the ion exchange resins | usually approx. 6 ... 10 years | ||

| material options | pressure vessels |

• glass-rintroductionorced plastic (GRP) • carbon steel (e.g. S235JR, P265GH) • stainless steel (e.g. 1.4404, 1.4571) |

|

| pipelines |

• polyvinyl chloride (PVC) • polypropylene (PP) • polyvinylidene fluoride (PVDF) • stainless steel (e.g. 1.4404, 1.4571) |

||

| valves |

• polyvinyl chloride (PVC) • polypropylene (PP) • polyvinylidene fluoride (PVDF) • stainless steel (e.g. 1.4408) |

||

| gaskets |

• ehtylene propylene diene monomer rubber (EPDM) • fluoroelastomer (FKM) • polytetrafluoroethylene (PTFE) |

||

| control options | regeneration, line change-over |

• fully automated, via PLC • manual operation (usually not recommended) |

|

| process monitoring |

• volume counter (standard) • differential pressure (standard) • electrical conductivity (standard) • sodium (option) • silicic acid (option) • total organic carbon (TOC) (option) |

||

–

2018-05-05 • water treatment made in Germany • Company Information • Privacy