← Home • Products • EDI ↓ Summary • Design Example • Applications • Technical Data • Downloads

EDI (short for Electrodeionsiation), also CEDI (short for Continuous Electrodeionsiation), is an electrochemical membrane process for polishing of →demineralised water, meaning for removal of trace dissolved solids from water.

Basically, EDI is a variation of electrodialysis. Demineralisation within an EDI-module occurs by applying an electrical field accross ion-selective membranes. The ion-selective membranes form chambers, which are filled with ion exchange resin. Cations and anions move within the electrical field in accordance with their respective electrical charge, and are then retained in concentrate chambers by the ion-selective membranes.

EDI is a continuous process. During operation, concentrate will continuously be either discharged as waste water, or recycled into an upstream process step.

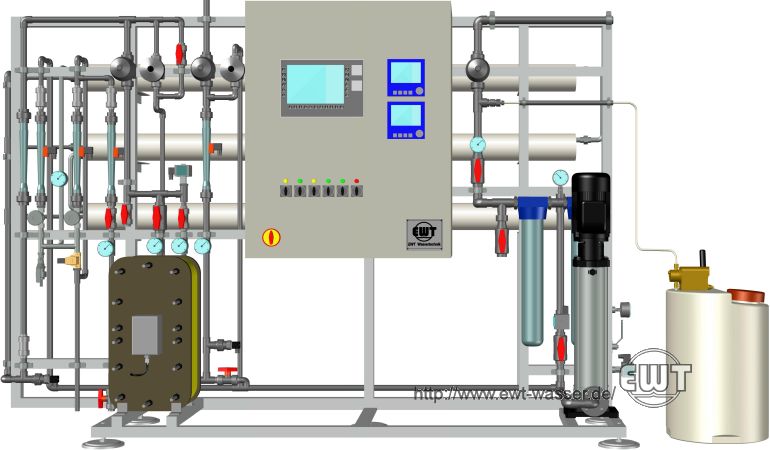

EDI plant, single line, skid-mounted together with an upstream reverse osmosis plant.

| product volume flow | available from approx. 0.5 up to 100 m³/h for each line | ||

| amount of lines | usually 1× 100% or 2× 50% | ||

| product quality | electrical conductivity | < 0.2 μS/cm | |

| silicic acid | < 20 μg/L SiO2 | ||

| recovery | 90% ... 95% | ||

| differential pressure at nominal flow | approx. 2 bar | ||

| operating pressure | ≤ 6 bar | ||

| operating temperature | 5 ... 40 °C | ||

| concentrate discharge | corresponding to the recovery, 50 ... 100 L for each 1 m³ product | ||

| concentrate quality | electrical conductivity | approx. 50 ... 300 μS/cm | |

| electrical energy demand | approx. 0.1 .... 0.3 kWh for each 1m³ product | ||

| recommended feed quality | source | reverse osmosis feed | |

| electrical conductivity | ≤ 30 μS/cm | ||

| free carbon dioxide | < 1 ... 10 mg/L CO2 | ||

| water hardness | < 0.01 mmol/L | ||

| iron | < 0.01 mg/L Fe | ||

| manganese | < 0.01 mg/L Mn | ||

| silicic acid | < 1 mg/L SiO2 | ||

| free chlorine | < 0.02 mg/L Cl2 | ||

| total organic carbon (TOC) | < 0.5 mg/L C | ||

| total service life of the EDI modules | usually ≥ 5 years | ||

| material options | module housing |

• polyvinyl chloride (PVC) • glass-rintroductionorced plastic (GRP) |

|

| pipelines |

• polyvinyl chloride (PVC) • polypropylene (PP) • polyvinylidene fluoride (PVDF) • stainless steel (e.g. 1.4404, 1.4539) |

||

| valves |

• polyvinyl chloride (PVC) • polypropylene (PP) • polyvinylidene fluoride (PVDF) • stainless steel (e.g. 1.4408) |

||

| gaskets |

• etyhlene propylene diene monomer rubber (EPDM) • polytetrafluorethylene (PTFE) |

||

| skid | • stainless steel (e.g. 1.4301) | ||

| control options | start-up, service, and shut-down |

• fully automated, via micro-processor control unit • fully automated, via PLC |

|

| process monitoring |

• gauge pressure (option) • differential pressure (option) • volume flow concentrate (standard) • volume flow product (option) • electrical conductivity product (standard) • silicic acid product (option) |

||

–

2018-05-05 • water treatment made in Germany • Company Information • Privacy