← Home • Products • Membrane Degasser ↓ Summary • Design Example • Applications • Technical Data • Downloads

Membrane degassing or membrane gas transfer is a membrane separation process for removal of dissolved gases from liquids, in water treatment especially for removal of carbon dioxide(CO2) and oxygen (O2) from water.

A membrane contactor is a device for membrane degassing, mainly consisting of an outer pressure vessel with inside hollow fibre membranes. Liquids flows through the pressure vessel and around the outside of the hollow fibre membranes. Depending upon the operating mode, there is either sweep gas flowing through the inside of the hollow fibre membranes, or they are being evacuated by vacuum pumps. Both will result in the gas diffusing from the liquid and through the hollow fibre membranes, to be either removed with the sweep gas or evacuated by the vacuum pumps.

Membrane gas transfer a continuous process. During operation, a small amount of waste water will need to be periodically discharged from the gas side, in addition to any cooling water requirements for the vacuum pumps.

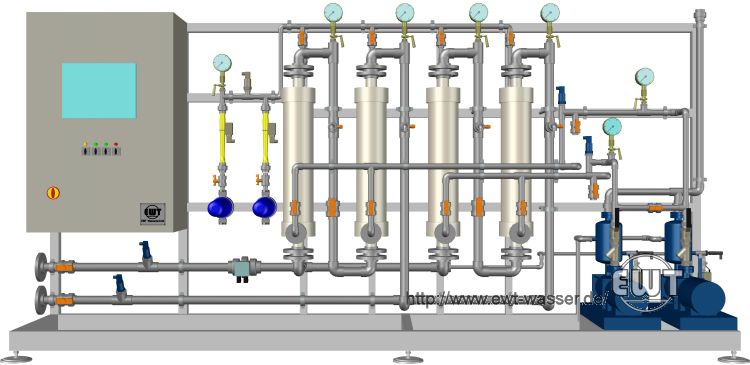

Membrane gas transfer plant for removal of CO2 from water, combined air sweep and vacuum mode, two lines, with two membrane contactors arranged in series for each line.

| degassed water volume flow | available from approx. 0.5 up to 150 m³/h for each line | ||

| amount of lines | usually 1x 100% or 2x 50% | ||

| degassed water quality | free carbon dioxide | < 5 ... 10 mg/L CO2, depending upon the process conditions | |

| oxygen | depending upon the plant design and process conditions | ||

| differential pressure at nominal load | approx. 0.2 ... 0.5 bar | ||

| operating pressure, absolute |

≤ 7 bar on the liquid side approx. 75 mbar on the gas side, for CO2-removal |

||

| operating temperature | 5 ... 30 °C | ||

| sweep gas |

• ambient air or compressed air, for CO2-removal • nitrogen, for oxygen-removal |

||

| sweep gas consumption | depending upon the plant design and the process conditions | ||

| waste water discharge | approx. 0.5 ... 2.5 L/day, plus any required cooling water for the vacuum pumps | ||

| recommended raw water quality | turbidity | < 0.5 NTU | |

| total suspended solids (TSS) | < 1 mg/L | ||

| Silt Density Index (SDI15 min) | < 3 %/min | ||

| total alkaline earths (hardness) | < 0.1 mmol/L | ||

| iron | < 0.3 mg/L Fe | ||

| free chlorine | < 0.5 mg/L Cl2 | ||

| surfactants | not detectable | ||

| total organic carbon (TOC) | < 1 ... 3 mg/L C | ||

| oil, grease | < 0.5 mg/L | ||

| total service life of the membrane contactors | usually approx. 3 ... 5 years | ||

| material options | membrane contactor |

• polypropylene (PP) • stainless steel (1.4404) |

|

| vacuum pump | • stainless steel (e.g. 1.4301, 1.4408) | ||

| pipelines |

• polyvinyl chloride (PVC) • polypropylene (PP) • polyvinylidene fluoride (PVDF) • stainless steel (e.g. 1.4541, 1.4571) |

||

| valves |

• polyvinyl chloride (PVC) • polypropylene (PP) • polyvinylidene fluoride (PVDF) • stainless steel (e.g. 1.4541, 1.4571) |

||

| gaskets |

• etyhlene propylene diene monomer rubber (EPDM) • polytetrafluorethylene (PTFE) |

||

| control options | start-up, service, and shut-down |

• fully automated, via control circuitry • fully automated, via PLC |

|

–

2018-05-05 • water treatment made in Germany • Company Information • Privacy