← Home • Products • Ultrafiltration ↓ Summary • Design Example • Applications • Technical Data • Downloads

Ultrafiltration (short: UF) is a membrane process for filtration of liquids, which in water treatment is used for removal of suspended solids and certain dissolved macromolecular substances (e.g. TOC-removal) from water.

Ultrafiltration – designed for dead-end operation in water treatment – is an intermitting process, with periodic backwashing between operating periods. For backwashing, filtrate is used, often enhanced by cleaning chemicals. Compared to other filtration processes, both the backwash duration and the operating periods are significantly shorter, allowing for a semi-continuous operation even with a single line design.

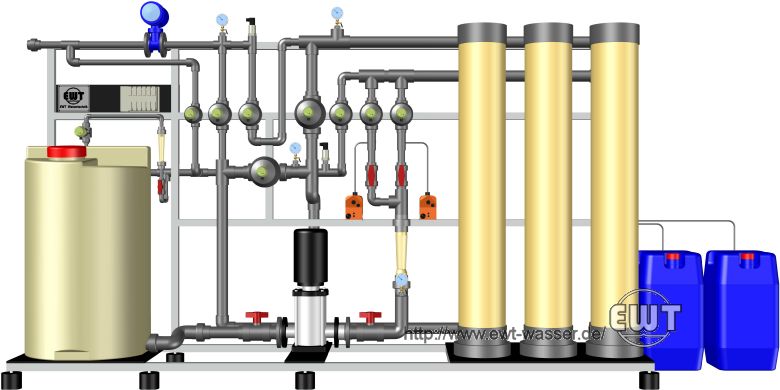

Ultrafiltration plant, single line, with three UF modules operating in parallel, chemically enhanced backwash.

| filtrate volume flow | available from approx. 1.5 up to 150 m³/h for each line | ||

| amount of lines | usually 1× 100% or 2× 50% | ||

| filtration grade | approx. 0.01 ... 0.1 μm | ||

| filtrate quality | turbidity | ≤ 0.1 NTU | |

| Silt Density Index (SDI15 min) | < 3 %/min | ||

| total organic carbon (TOC) | removal of approx. 20% ... 65% | ||

| differential pressure at nominal flow | approx. 0.2 ... 2 bar | ||

| operating pressure | ≤ 4 ... 10 bar | ||

| operating temperature | ≤ 20 ... 40 °C | ||

| backwash intervals | approx. 30 ... 180 minutes | ||

| backwash duration | approx. 30 ... 60 seconds | ||

| backwash water consumption | approx. 10 ... 150 L for each 1 m³ filtrate | ||

| chemicals for chemically enhanced backwash |

• hydrochloric acid (HCl) • citric acid • sodium hydroxide (NaOH) • sodium hypochlorite (NaOCl) |

||

| recommended raw water quality | turbidity | < 50 NTU | |

| total suspended solids (TSS) | ≤ 50 mg/L | ||

| particle diameter | < 300 μm | ||

| free chlorine | ≤ 0.5 mg/L Cl2 | ||

| total organic carbon (TOC) | < 10 mg/L C | ||

| oil, grease | < 0.5 mg/L | ||

| total service life of the UF modules | usually approx. 2 ... 5 years | ||

| material options | UF membranes |

• polyethersulfone(PES) • polyvinylidene fluoride (PVDF) |

|

| pressure vessels | • polyvinyl chloride (PVC) | ||

| pipelines |

• polyvinyl chloride (PVC) • polypropylene (PP) • polyvinylidene fluoride (PVDF) • stainless steel (e.g. 1.4541, 1.4571) |

||

| valves |

• polyvinyl chloride (PVC) • polypropylene (PP) • polyvinylidene fluoride (PVDF) • stainless steel (e.g. 1.4401, 1.4408) |

||

| gaskets |

• etyhlene propylene diene monomer rubber (EPDM) • polytetrafluorethylene (PTFE) |

||

| skid | • stainless steel (e.g. 1.4301) | ||

| control options | backwash |

• fully automated, via micro-processor control unit • fully automated, via PLC |

|

| process monitoring |

• differential pressure (standard) • volume counter (option) • turbidity (option) • total organic carbon (TOC) (option) |

||

–

2018-05-05 • water treatment made in Germany • Company Information • Privacy